Last night, in the ancient city of Xi'an where autumn rain fell softly, I still felt a slight chill even though I was wearing a jacket and thin long pants. Upon landing in Shanghai, the "Magic City," I couldn't help but take off my jacket as I walked out of the terminal, just to adjust my body temperature to fit the external environment. Humans are the most intelligent species on Earth, and what we call artificial intelligence (AI) all imitates the intelligent control functions of humans.

When the body's "skin"—serving as a sort of "temperature and humidity sensor"—detects that the external temperature is too high, it transmits this information through the "nervous system," which acts as a "communication system," to the "brain," the equivalent of a "processing system CPU." After the processor completes its calculations, it sends the information back through the communication system to the "two hands," which function as "actuators," prompting them to take off the jacket to adapt to the external environment. This is what textbooks refer to as "closed-loop control," and simple artificial intelligence just mimics this process and operation.

At the invitation of Mr. Zhou and Mr. Zhu from the China Sensor and Internet of Things Industry Alliance, I came to Jiading, Shanghai, to attend the 5th China Intelligent Sensor Development Conference. The Secretary of the Jiading District Committee attended the conference in person, as Jiading strives to build a highland for the integrated circuit and intelligent sensor industries.

However, as my friend Guo Yuansheng stated in his keynote speech, sensors only account for a small part of integrated circuits, and there are significant differences between the integrated circuit industry and the sensor industry. From Brother Gu's perspective, Jiading seems to conflate sensors and integrated circuits to some extent, yet at other times separates them. Of course, there are indeed sensors in the form of integrated circuits, especially MEMS sensors. In some cases, MEMS sensors are integrated with ASIC processors, combining sensing functions and integrated circuits into one. In these two scenarios, developing integrated circuits and developing intelligent sensors should be considered the same thing, because their basic processes are similar, and their requirements for talents, technologies, equipment, and workshops are also comparable.

For other types of sensors beyond these, it is difficult to categorize them under integrated circuits. Their development approaches should also be different, and their supply chains and industrial chains are not the same either. Brother Gu believes that Jiading District should appropriately adjust its thinking in terms of investment promotion policies and implementation.

Mr. Wu, the Chairman of Shenzhen Anpeilong Co., Ltd., was originally supposed to come in person, but due to a last-minute matter, he was replaced by the R&D Director to give a speech, which mainly focused on six-axis force sensors. Since humanoid robots have become a current and future hotspot in the sensor field, this topic aroused great interest among the audience. Anpeilong provided some conclusions through research and testing on the performance differences between metal strain gauges and MEMS silicon-based strain gauges when both are applied to six-axis force sensors, hoping to be helpful to everyone. In fact, six-axis force sensors can also be manufactured using other processes; for example, the piezoelectric principle can be used to produce high-frequency-response six-axis force sensors. Has anyone ever boldly tried to make six-axis force sensors using the optical fiber principle? If so, the modem should be extremely small.

We believe that based on our MCS technology platform, we will also be able to produce six-axis force sensors in the future, which is pending further development.

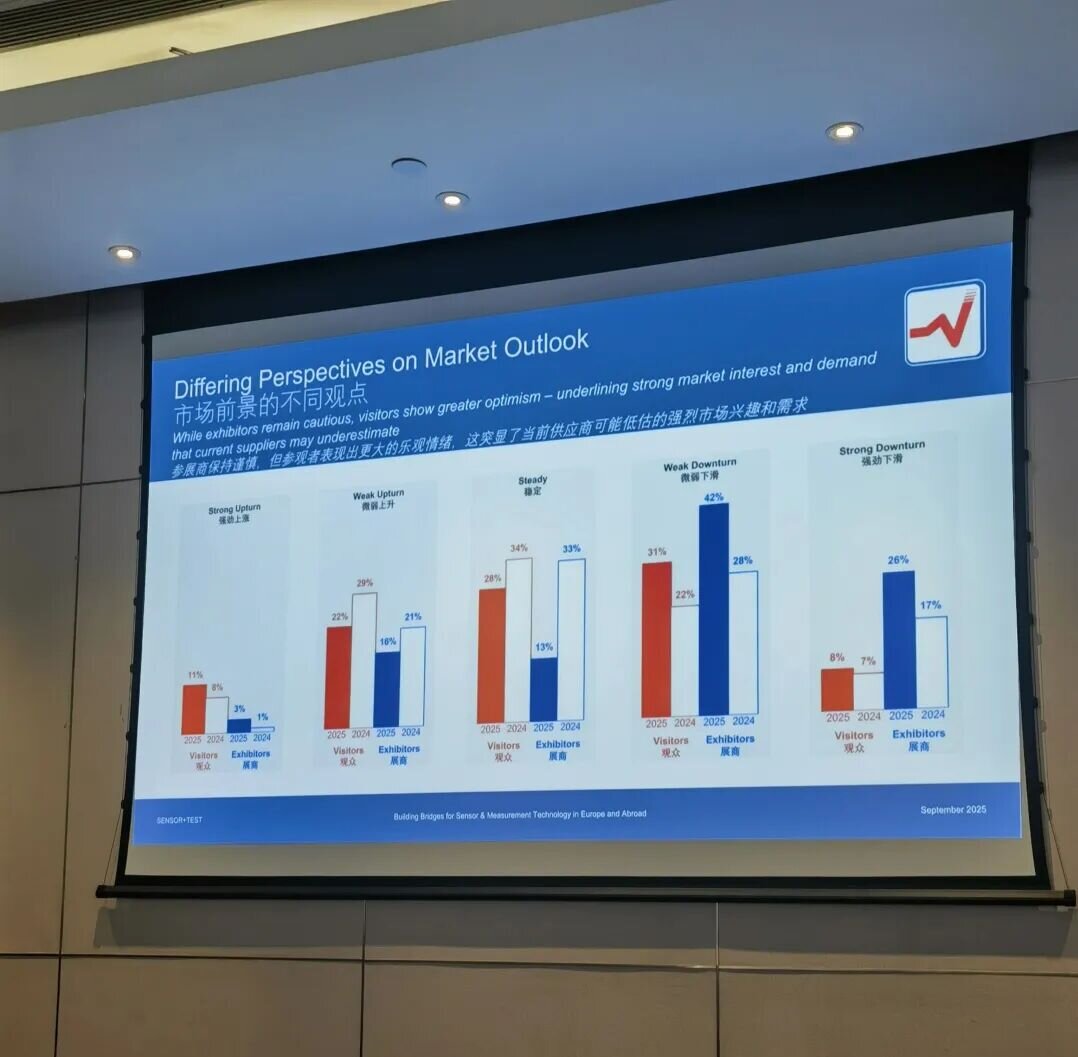

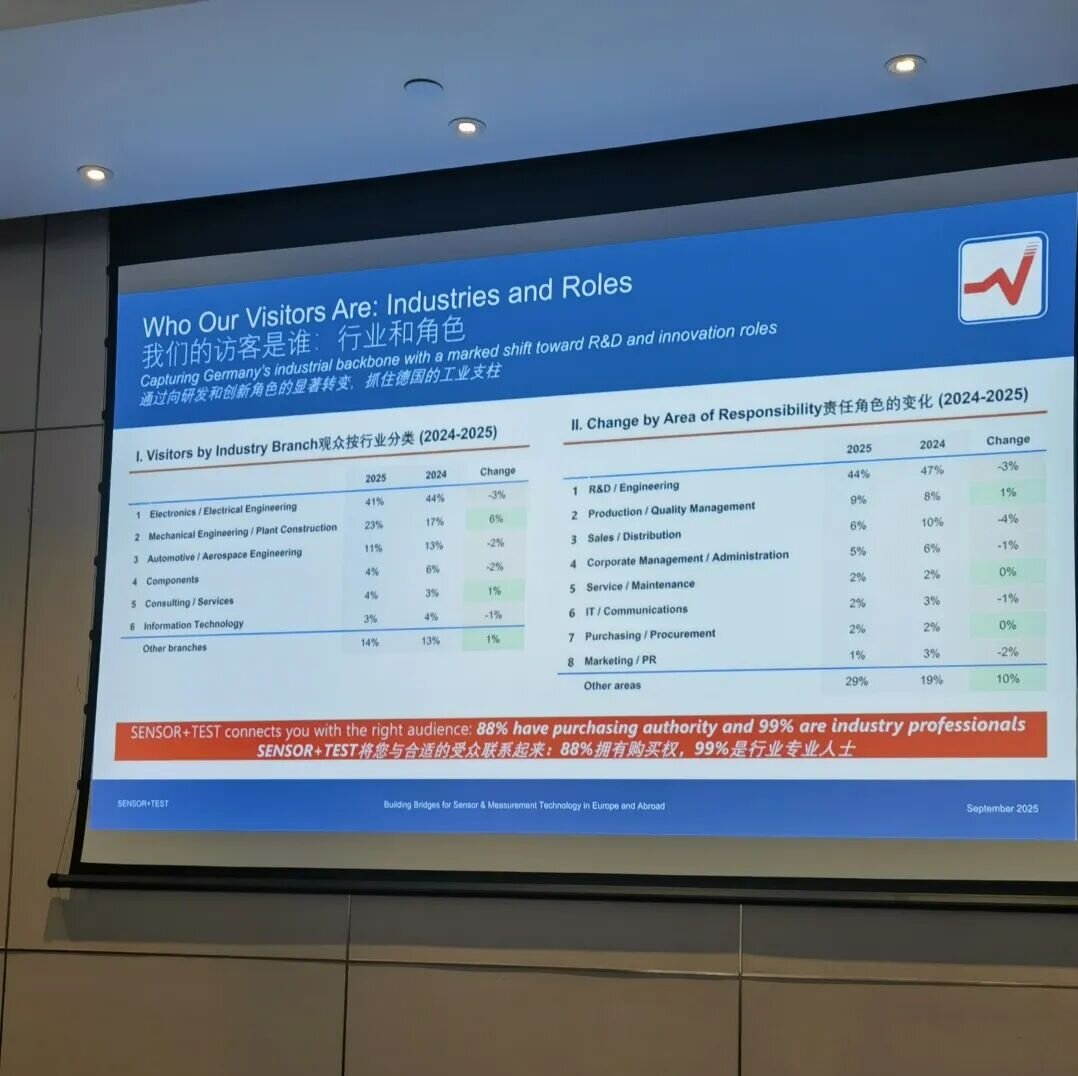

In the afternoon, according to the schedule, I attended the sub-forum on the overseas development of Chinese sensor enterprises. The new General Manager of the "Sensor + Test" Exhibition in Nuremberg, Germany, also came to the conference. The German side gave a PPT presentation on the German Sensor Exhibition, covering the different views of exhibitors and visitors over the 2024–2025 period, as well as the composition of the visitors' origins. Readers who are interested can take a close look at the two charts below.

During the sharing session on the experience of sensor enterprises going global, two old friends—Mr. Lü from Hangzhou Melek and Mr. Shen from American Shengmi Technology—shared their experiences. Mr. Lü's experience was macroscopic and strategic, while the report by Mr. Shen, an overseas Chinese, was specific and actionable. Both are worthy of learning and reference for Chinese sensor enterprises going global, and some suggestions can be directly applied.

Friends who are attentive can take a detailed look at Mr. Shen's specific suggestions.

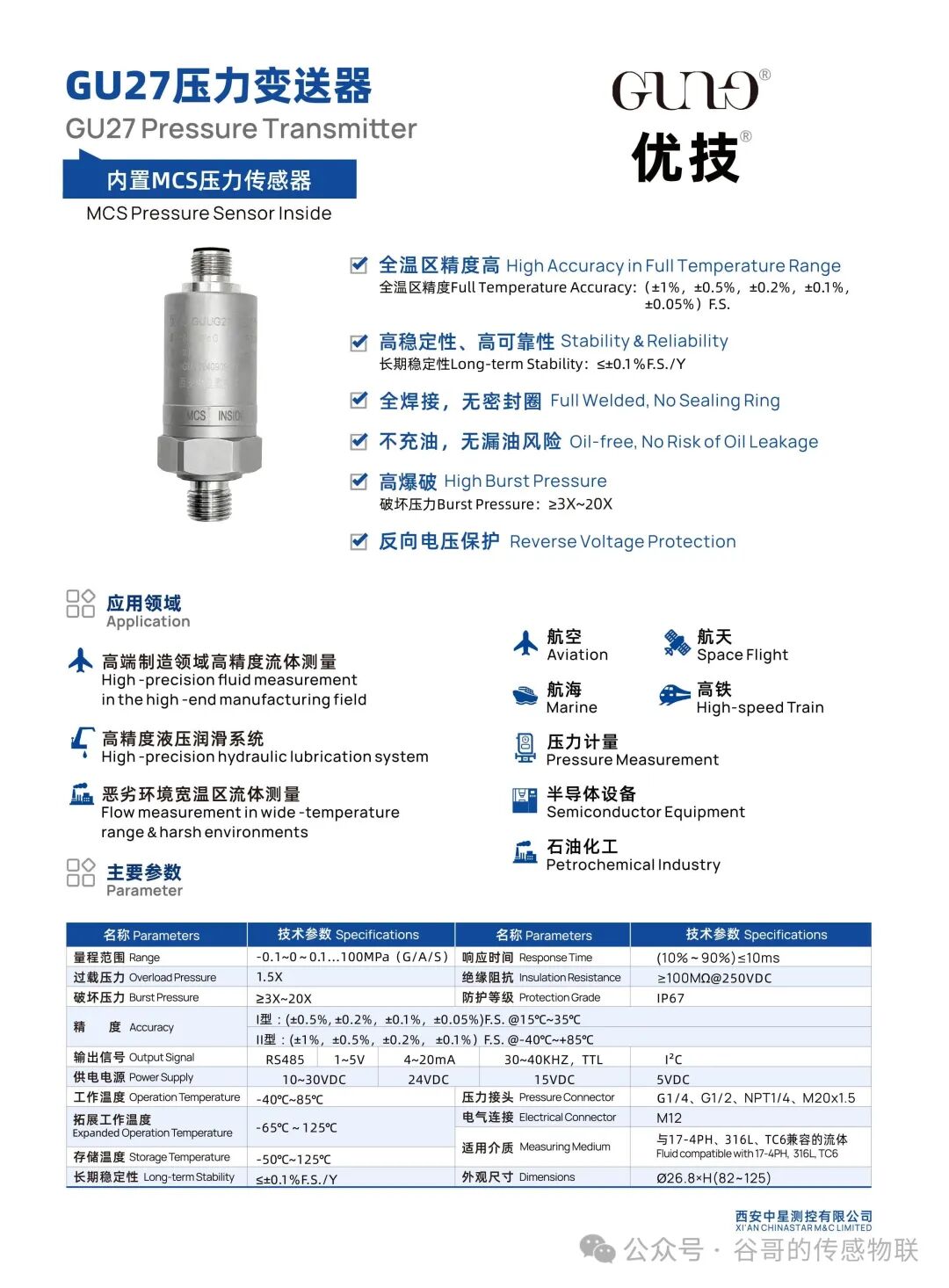

Next to the sub-forum on enterprise globalization, there was another sub-forum on semiconductor equipment. Brother Gu also dropped by this sub-forum and happened to catch the part where the organizer, Mr. Zhang, asked everyone to introduce their respective companies and their characteristics one by one. Brother Gu focused on introducing the MCS high-end pressure sensor technology and products that Xi'an Chinastar M&C Co., Ltd. has been developing for 11 years. For Chinese semiconductor and semiconductor equipment enterprises that are severely sanctioned by the United States, localization is an unavoidable topic.

The MCS pressure sensors of Xi'an Chinastar M&C Co., Ltd. have a measurement range from a high pressure of 200 MPa to a low pressure of 100 kPa. More importantly, they have three key advantages: First, they have exclusive intellectual property rights, independent and controllable technology, and all materials are localized. Second, unlike the commonly used MEMS oil-filled cores (which raise concerns about equipment contamination due to oil leakage), the MCS pressure cores of Zhongxing Measurement & Control have no oil, eliminating any such worries. Third, the elastomer that comes into contact with the measured medium can be made of different metal materials, specified by the user.

It was a busy day, and I met many friends. Every meeting is not only an opportunity to learn but also a chance to meet and chat with friends, deepening our friendship.

Tomorrow, the Sensor China Exhibition in Shanghai will officially open, and we are moving towards becoming the world's largest sensor exhibition.

#2025.09.23.20:38 Shanghai Jiading Sheraton Hotel#

Release Date:2025-09-24

Release Date:2025-09-24  Click on the quantity:458

Click on the quantity:458