At present, China's fog and haze is increasing every day, and motor vehicle emissions have become an important source of pollution. In the motor vehicle, the most serious pollution is from diesel vehicles. In our country the development of diesel cars started late, and the importance gasoline despise diesel light" development policy make diesel engine technology be in a backward state for a long time, some old diesel car fuel consumption is high, noise big, black smoke rolling.

Aiming at this situation, After nearly four years of research and development, testing and experimentation, Xi'an Chinastar M&C LTD launched a special pressure sensor CS-PT1376 for diesel engine exhaust processing device (SCR), Main Diesel exhaust emissions is NOX, after dealing with the SCR system it become N2 and water vapor, in line with the European V that the country V standards, significantly improve the quality of the environment.

From the anti vibration, corrosion resistance, urea icing is not damaged, such as the requirements CS-PT1376 pressure sensor complete match SCR system. At present, Xi'an Chinastar M&C LTD has applied for national patent for CS-PT1376 pressure sensor.

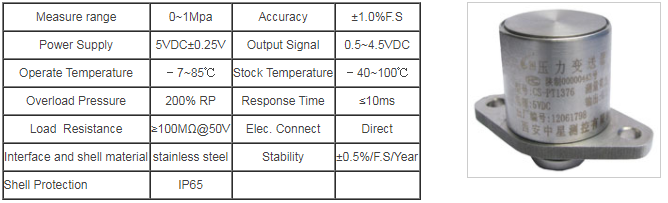

Technical parameters

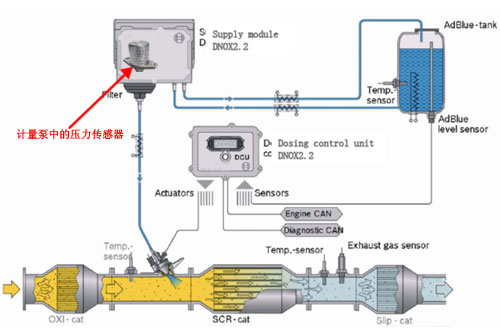

Application

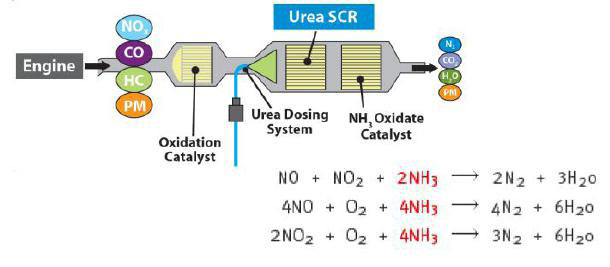

SCR system and urea injection

1.SCR: selective catalytic reduction

2.Urea solution inject into tail gas emission system

3.NOX emissions decreased by more than 80%

4.Urea injection pressure sensor pressure range of 10Ba

Urea solution for vehicle

1 Conform to DIN 70070

2, 32.5% urea solution

3, urea

4, the temperature dropped to -11 degrees Celsius below the solution will freeze

5, the volume will be expanded after the freeze about 10%

6, urea solution will be decomposed at 80~120

7, the solution in the drying process will appear urea crystallization

The challenge of SCR system for pressure sensors

1, the frequent vibration requirements of the product from automotive industry.

2, the corrosion of urea solution

32.5% urea solution (Ad Blue) is alkaline, pH value is about 10 so there is a high demand to the sensor housing and sealing the original corrosion resistance.

3, urea solution freezing problem

The urea solution can be frozen at -11, and the volume expansion is about 10%. If urea is residual sensor internal under low temperature, it will be freezing and cause generating huge pressure (up to tens of MPA in the internal sensors), resulting in the destruction of the structure of the sensor and sensor.

Release Date:2021-03-09

Release Date:2021-03-09  Click on the quantity:16828

Click on the quantity:16828