After attending the full-day 2025 China Sensor Industry Development Conference in Baoying, Yangzhou, I listened to experts and leaders deliver speeches on sensor-related strategic overviews, industry analyses, technical elements, and future trends. Gu Ge (the author) also shared insights on "The Road to Localization of Industrial Pressure Sensors".

Subsequently, I participated in the discussion of the Sensor Comprehensive Group, attended half of the dinner banquet, said goodbye to industry friends, and rushed to Baoying High-Speed Railway Station.

On this autumn night in Baoying, the autumn wind brought a distinct chill, prompting me to wrap my jacket tighter. It was nearly 8 o’clock, and I had an approximately one-hour high-speed rail ride ahead to my next destination—Taizhou.

I arrived in Baoying at 17:30 yesterday and am leaving now, making this a 26-hour trip to Baoying. I felt the warmth of the reception staff and workers in Baoying County, joined the "final part" of the 2025 Council Meeting of the Sensitive Components and Sensors Branch of the China Electronic Components Association, learned about Baoying County’s history and key industries through introductions by county leaders, and absorbed sensor technology and industry reports from many experts. Instead of elaborating on each detail here, Gu Ge would like to share the speeches of some entrepreneurs at the Comprehensive Group discussion—each with unique features and truly remarkable.

#2025.10.16.21:48 G2577 Baoying/Taizhou#

The discussion of the Comprehensive Group under the Sensitive Components and Sensors Branch of the China Electronic Components Association was co-hosted by General Manager Li from Nanjing Gaohua Technology Co., Ltd. and General Manager Li from Mianyang Weibo Electronic Technology Co., Ltd. More than 20 representatives from across the country attending the discussion respectively shared their companies’ current status and expressed their views on the current development of the sensor industry.

In short, their views can be summarized as follows:

First, severe internal competition in the current sensor industry is a consensus among most enterprises. For example, a certain electronic company in Chengdu, which mainly produces ultrasonic sensors (primarily used in reverse parking radars), has seen increasing output in recent years but no corresponding growth in revenue. The company’s goal is simply to "survive through perseverance". They humorously said, "As long as we don’t wear out the boss and the company doesn’t collapse, that’s a victory." Jokes aside, they are actually making every effort to transform, explore new breakthroughs and application scenarios, rather than just focusing on ultrasonic components. A certain electronic company in Qingdao uses special magnetic sensors to produce speed sensors and magnetic encoders. Their slogan under the current situation is particularly inspiring: "Ensure survival, strengthen internal capabilities, and move forward steadily (literally ‘turtle-paced progress’)". Isn’t this slogan both striking and practical?

Amidst current export obstacles and intensified domestic circulation, internal competition is not limited to the sensor industry—it is even more fierce in the downstream component industry (i.e., the supply side of sensors). For instance, a company in Sichuan that mainly produces resistors finds the industry competition extremely intense. They planned to move upstream to produce sensors, only to discover that the sensor industry is equally competitive. Similarly, a company in Ningbo that used to produce potentiometers transitioned to manufacturing electrical quantity sensors. Though the prospect sounded promising, the journey remains tough—after over a decade of R&D efforts, their annual sales are only around 30 million RMB. General Manager Ding from Shandong Baice Technology Co., Ltd. also mentioned that their company shifted from producing pressure transmitters to pressure sensors (specifically oil-filled pressure sensor cores), hoping to move from a "red ocean" (highly competitive market) to a "blue ocean" (untapped market). However, they soon realized that the pressure sensor core industry is just another "red ocean".

Nevertheless, some believe that competition in the sensor industry is not intense enough. General Manager Liu from Beijing Jiuhao Technology Co., Ltd. openly stated that compared to the integrated circuit (IC) industry, the sensor industry is far less competitive. On the other hand, he argued that only through rigorous competition can higher quality and higher standards be achieved.

Industry competition is inevitable. General Manager Li from Nanjing Gaohua Technology emphasized that we should compete in terms of technology, quality, and brand—not just price. Facing competition, General Manager Ding from Shandong Baice also strives to enhance the company’s brand, pursue differentiation (adapting to different working environments), and focus on segmented, differentiated, and high-end product positioning.

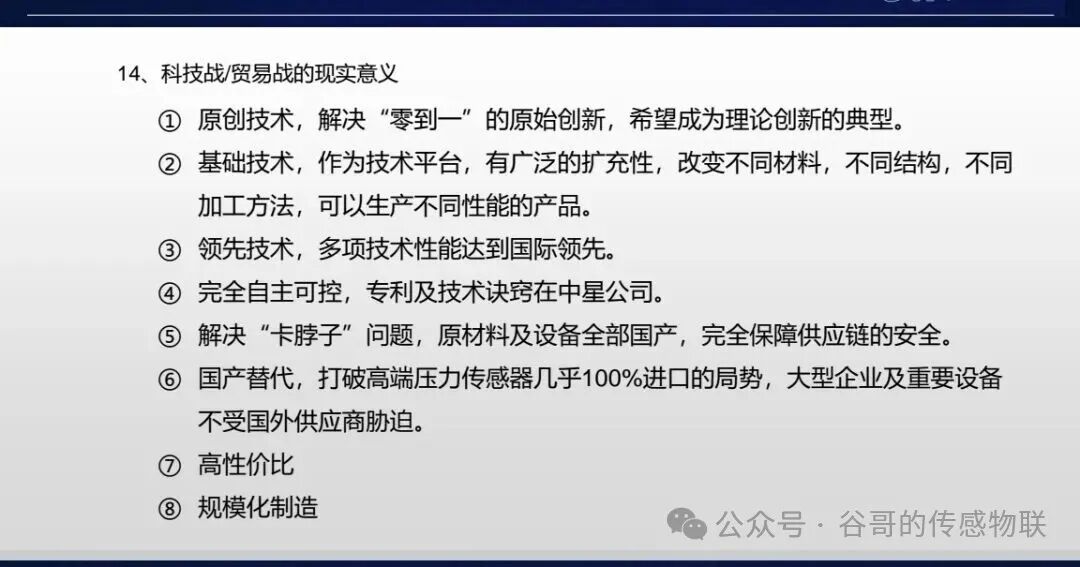

Second, persist in innovation and original R&D. Hangzhou Melek Co., Ltd., which produces high-end optical sensors and optical filters, believes that during the 15th Five-Year Plan period (2026–2030), amid the fierce Sino-foreign technological war, China’s original sensor technologies and products will have greater opportunities. Localization substitution is not only a national requirement but also an inevitable trend in technological and market development.

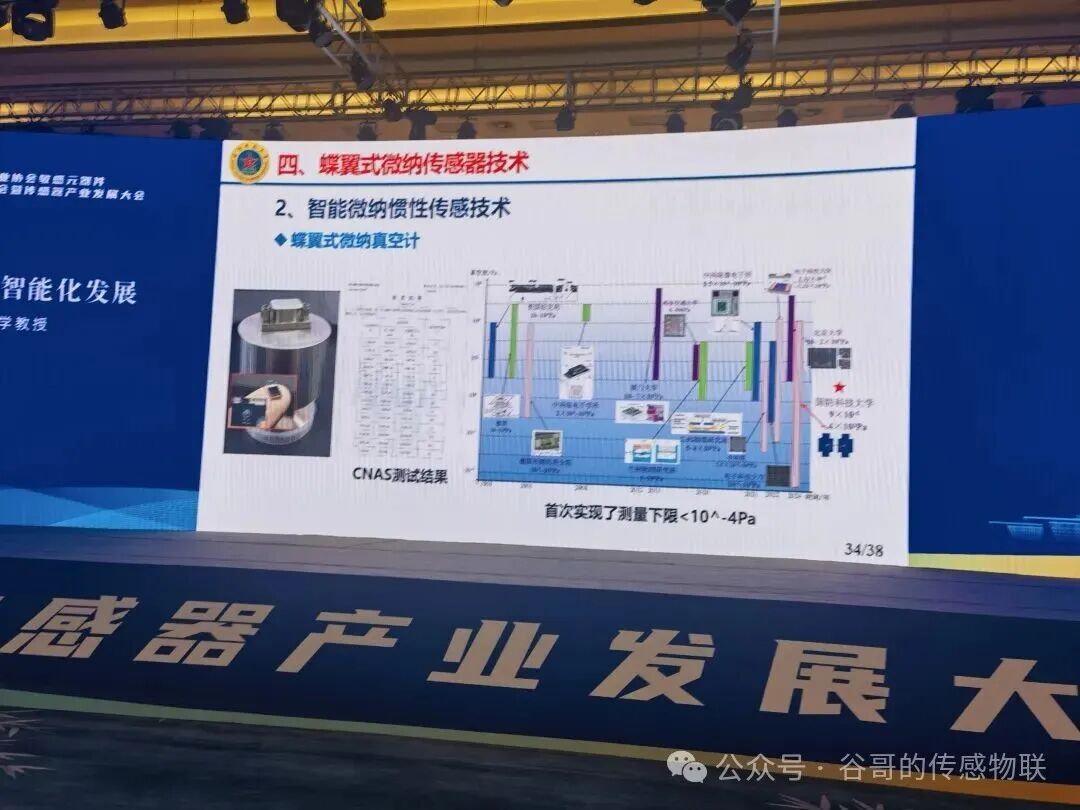

Professor Wu from the National University of Defense Technology has persisted in original innovation for decades and achieved remarkable technological breakthroughs in MEMS gyroscopes, accelerometers, and vacuum pressure sensors. Moreover, he has successfully transformed these technologies into practical products. He stressed the necessity of original innovation for the future development of China’s sensor industry—only through original R&D can China surpass foreign counterparts.

In Gu Ge’s speech today, the importance of original technologies (such as the MCS pressure sensor technology independently developed by Xi’an Chinastar M&C Co., Ltd.) and the use of Chinese raw materials amid the current technological and trade wars was also highlighted.

Third, amid the current competitive environment, enterprises are exploring ways to find "opportunities for survival and success". General Manager Song from Beijing Tiangong Junlian stated that their force sensors strive to match the performance level of foreign products while maintaining comparable prices. The entire company is focused on this single product category, and they believe this focus will surely help them seize opportunities for survival and development. Jiangsu Lianneng Technology produces accelerometers and vibration sensors. Amid competition, the company not only manufactures sensor bodies but also integrates them with various application scenarios—this approach not only enhances competitiveness but also boosts sales revenue.

Fourth, some enterprises in the industry are performing exceptionally well, mostly thanks to their connection to the booming new energy vehicle (NEV) sector (i.e., NEVs have become their clients). Shenzhen Jiangbeichuan Co., Ltd. mainly produces temperature sensors and thermistors for NEVs. Their other product—high-voltage capacitors for NEVs (not a sensor)—is currently in high demand; despite working overtime, supply still falls short of demand. A technology company in Hefei produces sintering equipment. Benefiting from leading technology and the surging demand for NEV IGBT modules, this 30-employee company achieved an output value exceeding 100 million RMB in 2023. The key reason behind this success lies in their possession of high-end talents and technologies, enabling them to compete in terms of both technology and quality.

As I write, it’s already past 11 PM. It’s time to rest—I have important client visits tomorrow.

#2025.10.16.23:13 Taizhou Fenghuang Hot Spring Hotel#