As the Qingming Festival approaches, a cold snap in northern China has caused the temperature in the ancient city of Xi'an to drop significantly. When I took a car to the airport in the morning, I still felt bursts of coolness.

This is my first domestic trip in 2025. I'm going to Shenzhen to attend the Shenzhen International Sensor Exhibition. At the same time, I also need to investigate which areas in Shenzhen are suitable for sensor enterprises to settle down. Some sensor businesses of Chinastar M&C hope to be based in Shenzhen to get closer to the market and customers and better serve international clients.

Yesterday morning, a working conference on the sensor and Internet of Things (IoT) industrial chain in Shaanxi Province was held at Shaanxi Electronic Information Group. I learned that despite the sluggish global economy in 2024, the sensor and IoT industry in Shaanxi Province still achieved good results. However, compared with Guangdong, Jiangsu, and Zhejiang provinces, it is still relatively backward. To some extent, Shaanxi's previous relative advantages in the sensor field are gradually fading away. This is a question that every person in the sensor industry in Shaanxi and those who care about the sensor industry in Shaanxi should think about.

Yesterday, when I was browsing the news on my mobile phone, I suddenly saw that Shenzhen Xinkailai Company made a stunning appearance at the semiconductor exhibition. It seems that the company has produced all the equipment for the main processes in the semiconductor equipment industry. As an outsider, I'm not clear about the actual usage situation of its specific customers, but I'm more concerned about the performance of the semiconductor devices produced using Xinkailai's semiconductor equipment.

I imagine that these high-end semiconductor devices must require various high-end sensors, and there must be a great demand for optical sensors. As far as I know, for micro absolute pressure sensors with ranges of 1 Torr and 10 Torr, that is, 0.133 kPa and 1.33 kPa, the domestic industry still needs to work harder in terms of accuracy, stability, and service life.

Semiconductor equipment also uses pressure sensors with relatively large ranges, such as 100 kPa, 1 MPa, and other different ranges, with high accuracy requirements, and the comprehensive accuracy is 0.1%. Currently, most of them use foreign MEMS oil-filled cores, but there is a risk of silicone oil leakage, which is absolutely not allowed for such expensive semiconductor equipment. In this case, the MCS pressure sensors of Chinastar M&C, with the characteristics of low range, high accuracy, and no oil filling, will be of great use.

#2025.03.29.8:56 Sichuan Airlines 3U3171#

As soon as I got off the plane this afternoon, I visited Mr. Chen, an elite in the investment field at Shenzhen Talent Share Investment Management Co., Ltd. For those of us who have been engaged in technical research in the industry for a long time, we should learn more about capital and finance. After chatting for a few hours, I indeed learned a lot of knowledge and experience that we technical workers should make up for.

We had in-depth exchanges and discussions, and also thought about how to jointly promote the development of sensor technology and industry in Xi'an, Shaanxi, so as not to lag behind others. To be honest, we don't have enough confidence to say that the sensor industry in Shaanxi is leading the whole country. We specifically explored the possibility of setting up a sensor development fund and using our respective advantages to jointly promote the development and progress of sensors and make contributions to the future intelligent society and AI society. No matter how long the road ahead is, it starts with the first step. We must take action.

We had in-depth exchanges and discussions, and also thought about how to jointly promote the development of sensor technology and industry in Xi'an, Shaanxi, so as not to lag behind others. To be honest, we don't have enough confidence to say that the sensor industry in Shaanxi is leading the whole country. We specifically explored the possibility of setting up a sensor development fund and using our respective advantages to jointly promote the development and progress of sensors and make contributions to the future intelligent society and AI society. No matter how long the road ahead is, it starts with the first step. We must take action.

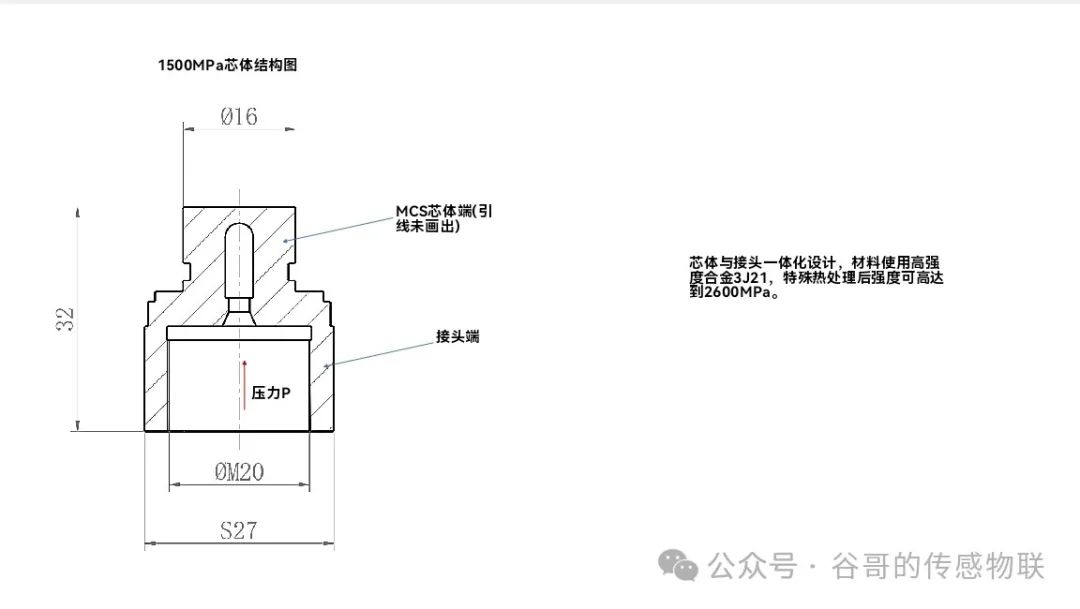

First, the pressure sensor with a range as high as 1500 MPa. In simple terms, it can measure the seawater pressure at a depth of 15 kilometers under the sea. Of course, there is no such deep seawater in the world. It is understood that the selling price of such a sensor abroad is more than 10,000 euros. Of course, with MCS technology, it is completely possible to develop a pressure sensor with such a high range, and its accuracy can fully meet the needs of customers. In the next step, we will develop a pressure sensor with a range as high as 1800 MPa. It is said that no company in the world has developed a pressure sensor with such a high range yet. We hope we are lucky enough to create another world first.

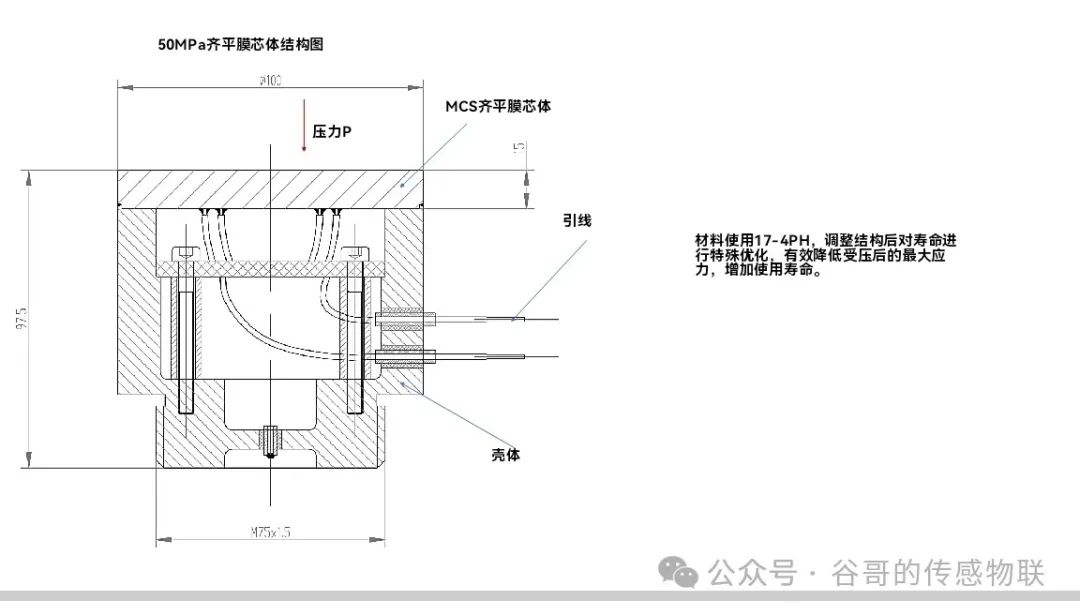

Second, a railway technology customer needs a pressure sensor with a range of 50 MPa, and requires it to have a long service life of up to 50 years or even 100 years, which is mainly used for the long-term real-time monitoring and management of railway facilities. The core diameter of a single sensor will reach 80-100 millimeters, which can be regarded as a "giant" pressure sensor.

The MCS pressure sensor technology is original, and our Chinastar M&C has mastered all the technical details. Moreover, all the materials currently used are domestically produced. Therefore, at this stage, we will focus on solving the customization needs of some special customers, especially in the urgent scientific and technological task of "domestic substitution" nowadays.

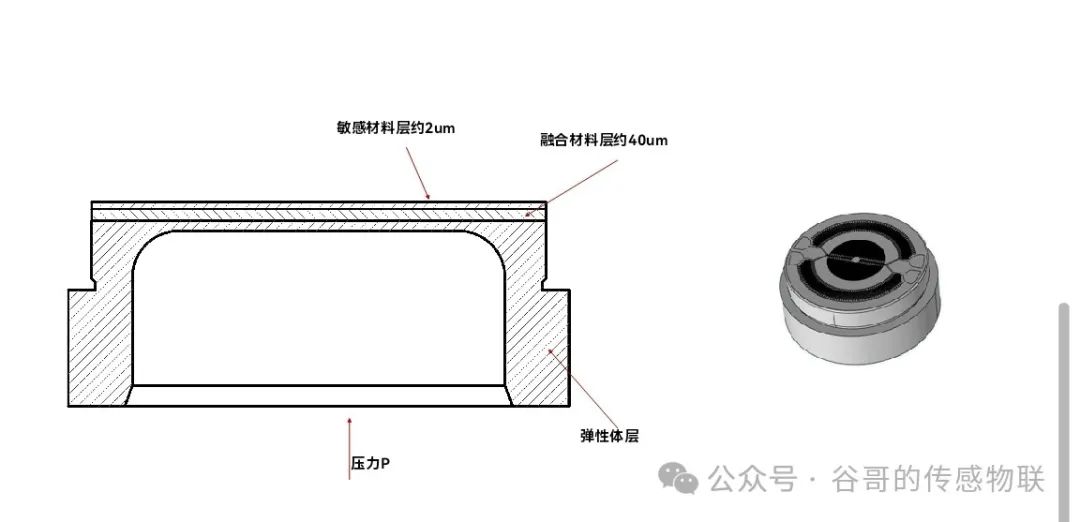

The principle is quite simple, but the manufacturing processes are very different. People in the sensor industry often say that making sensors is actually a craftsmanship. Whoever has better craftsmanship will have better product stability and higher quality. The core of the MCS pressure sensor is basically composed of three parts, and all three parts are variable, "the materials can be changed, the size can be changed, the shape can be changed, and the processing technology can be changed", so it can of course meet the customized requirements of many different industries.

The cold air has reached Shenzhen, so the temperature in Shenzhen today is almost the same as that in Xi'an. Wearing the same clothes as in Xi'an, I didn't feel the slightest bit of "warmth" in Shenzhen.

#2025.03.29.19:28 Carlton Hotel, Shenzhen#